Working with weighing stations

How to work with weighing stations

To control and account for cargo, large enterprises use weighing stations. The principle of operation of the weighing station is very simple: a car with a load drives onto the weighing platform, the value stabilizes and after that the system automatically records the readings.

Measurements are taken at the exit empty and at the entrance of the car already loaded. Thus, two indicators remain in the system, the difference between which is the weight of the load. To identify these events, we recommend using an RFID identification system.

In order to effectively use such equipment, outdated weighing models are often re-equipped with digital weighing terminals. It is to them that UMKu can be connected using the MyLogic script. At the moment, all weights that we encountered have been connected to the UMK and integrated into the GLONASSSoft monitoring system.

Support for weight stations in GLONASSSoft

In order for the system to start analyzing data from the weighing terminal, it is necessary to create a sensor with the Weighing terminal type in the object that is the weighing terminal in the system.

Sensor type The weighing terminal is located in the Agro group, in the drop-down list of sensor types.

You can see how the sensors are configured in the article: Sensors .

After creating a sensor with the Weighing terminal type, an event template with the name Weighing terminal will appear in the Templates tab.

The standard conditions for determining the weight are:

- Change in weight by more than 200 kg

- Weighing time should be 30 seconds or more

The event is generated if the readings of the "Weight terminal" sensor have reached a certain value and do not change for a certain period of time.

In the GLONASSSoft monitoring system, you have the opportunity to build two tables based on data from weighing terminals, these are the Plumb and Weight tables .

The Plumb and Weight tables are subreports of the Track report.

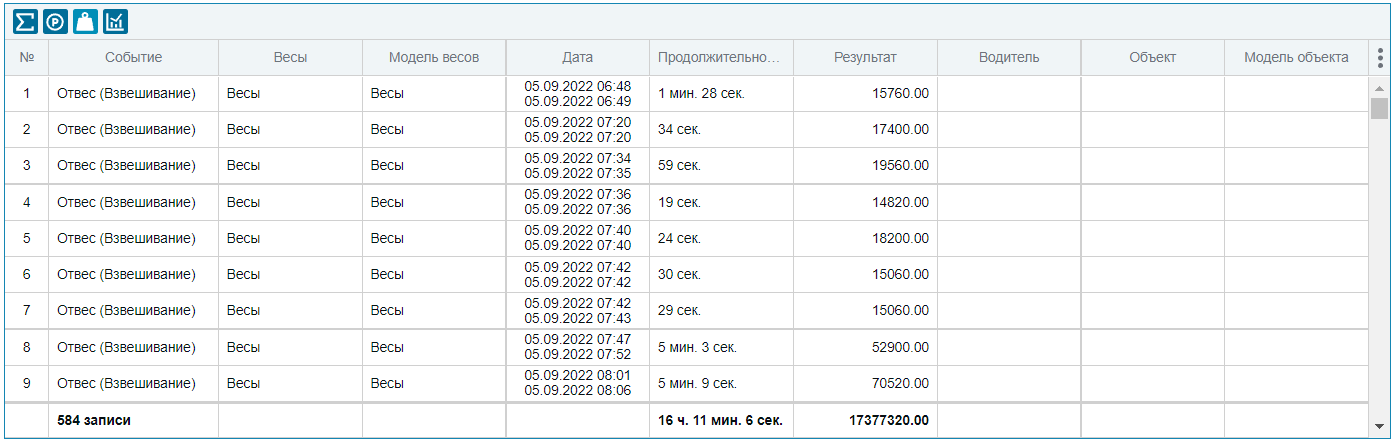

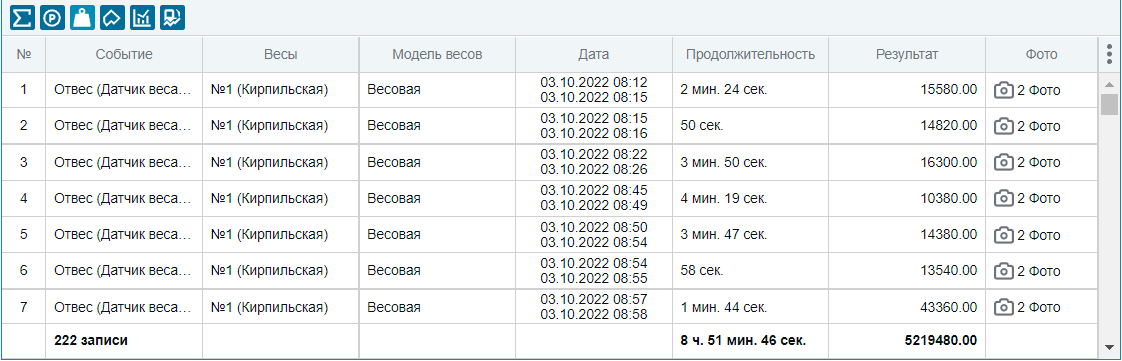

plumb lines

To generate the Plumb bob table, it is necessary to have a sensor of the Weight terminal type . Also, to identify the driver, the name and model of the object by RFID, you can specify a sensor of the driver RFID type. The table allows you to get ungrouped weighing data, even without reference to the weighed objects.

The plumb table consists of the following columns:

- Event: The name of the report and the name of the sensor by which the event was determined;

- Scales: Weighing terminal object name

- Scale Model: Weighing Terminal Object Model

- Date: Date and time of the start and end of the event

- Duration: The duration of the event. The format is adjusted by changing the duration format in the user settings . The setting is located in the "Reports" section, "General settings" block.

- Result: The median value of the sensor of the Weighing terminal type for the period of the event is displayed

- Driver: The driver of the weighed vehicle identified by the RFID tag

- Object: Weighed object, determined by connections with the driver

- Object model: Model of the weighed object, determined by the connections with the driver

The object to be weighed is determined by data from the driver's RFID card during the weighing period. Conditions for defining an object:

- If several different values of the RFID driver were transmitted during the weighing period, the very first value for the event period will be taken

- If the driver identified by the RFID value has links to multiple objects, then the object where the default driver is selected will be selected.

Also summarized below are the final data on the number of weighings for the specified time interval, the total duration of weighings and the total weight of the cargo.

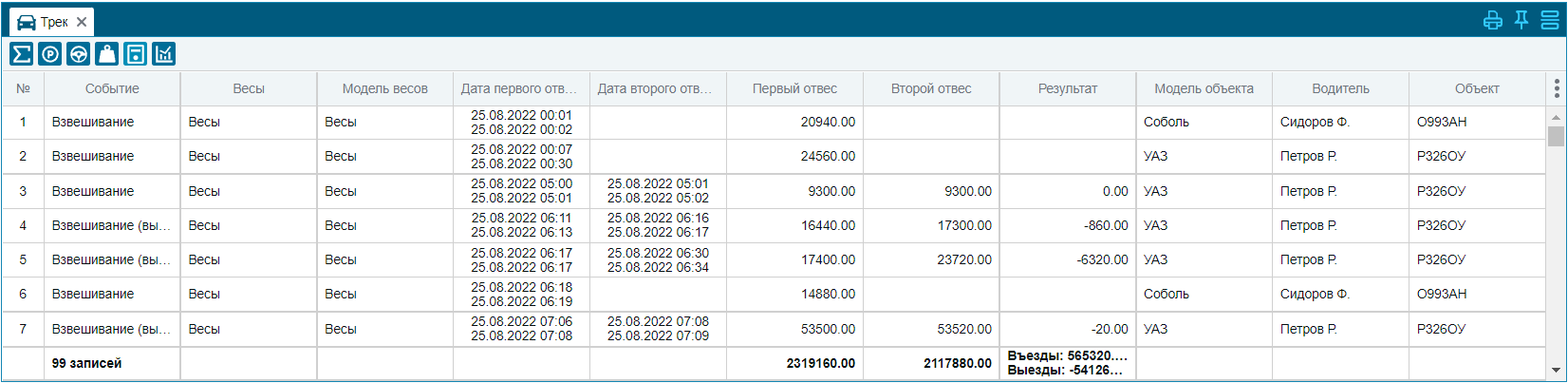

weigh-ins

To form the Weighing table , it is necessary to have both a sensor of the Weighing terminal type and a driver RFID type.

The plumb table consists of the following columns:

- Event: Specifies the name of the report and the type of the Entry/Departure/Weighing event. Entry/Departure depend on the value of the "Result" field, if the final value is a positive number, then the Entry event is indicated, if negative, then Departure. If the result is zero, or if the final result is not calculated, since there was no second event, then "Weighing" is displayed

- Scales: Weighing terminal object name

- Scale Model: Weighing Terminal Object Model

- Date of the first plumb: Date and time of the beginning and end of the first event

- Date of the second plummet: Date and time of the beginning and end of the second event

- First plumb: Displays the median value of the Weighing Terminal sensor for the period of the first event.

- Second plummet: Displays the median value of the weighing terminal sensor for the period of the second event.

- Result: The difference between the first and second plumb lines is displayed.

- Driver: The driver of the weighed vehicle identified by the RFID tag

- Object: Weighed object, determined by connections with the driver

- Object model: Model of the object being weighed, determined by the connections with the driver

The object to be weighed is determined by data from the driver's RFID card during the weighing period. Conditions for defining an object:

- If several different values of the RFID driver were transmitted during the weighing period, the very first value for the event period will be taken

- If the driver identified by the RFID value has links to multiple objects, then the object where the default driver is selected will be selected.

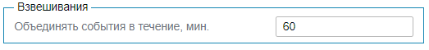

If during the report generation period there were more than one "Weigh-in" events with the same driver identified by RFID, then these events are combined into one report record, according to the "Combine events during, min" setting located in the User Settings - "Reports" section.

The default is 60 minutes.

Also summarized below are the final data on the number of weighings for the specified time interval, the total value of the first plumb line, the total value of the second plumb line and the total weight of the results.

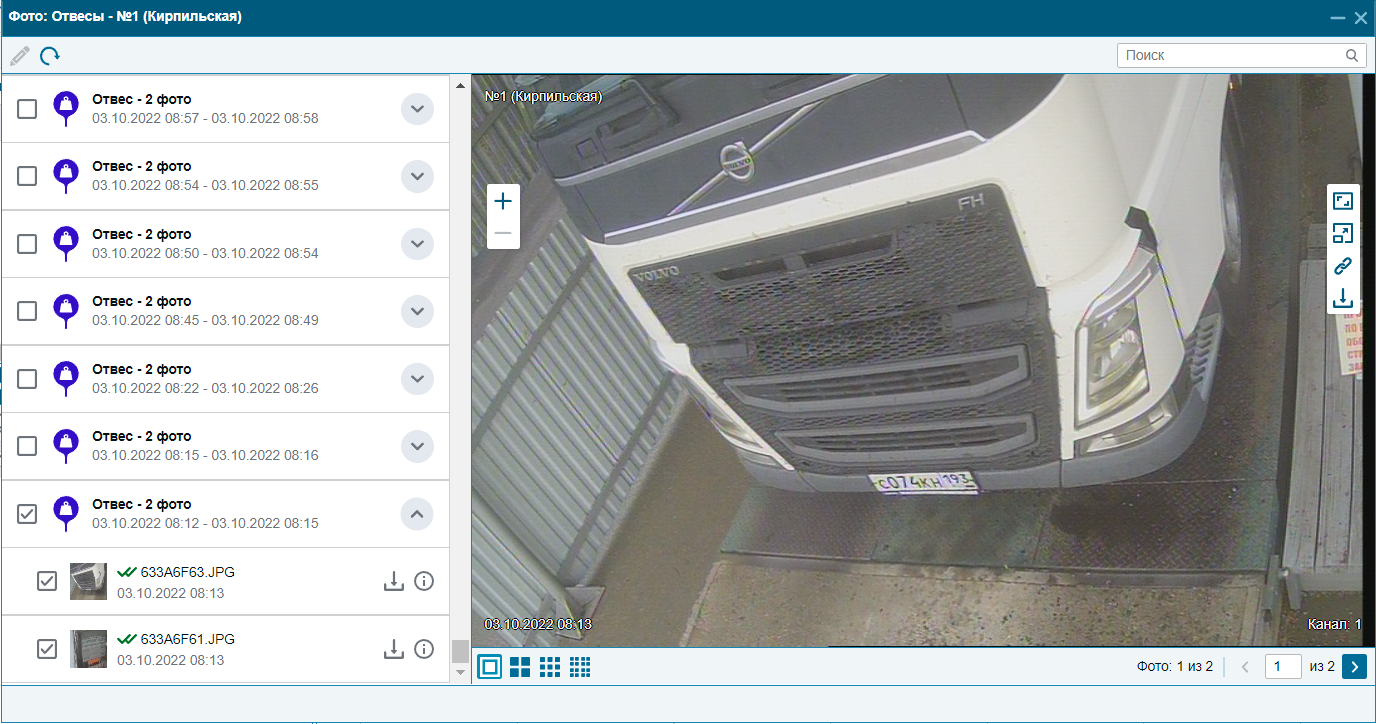

If during the weighing period photos were received from the terminal into the system, they will be added as in a table.

Clicking on the photo in the line will open a window with photos that were taken during the weighing.